Share On

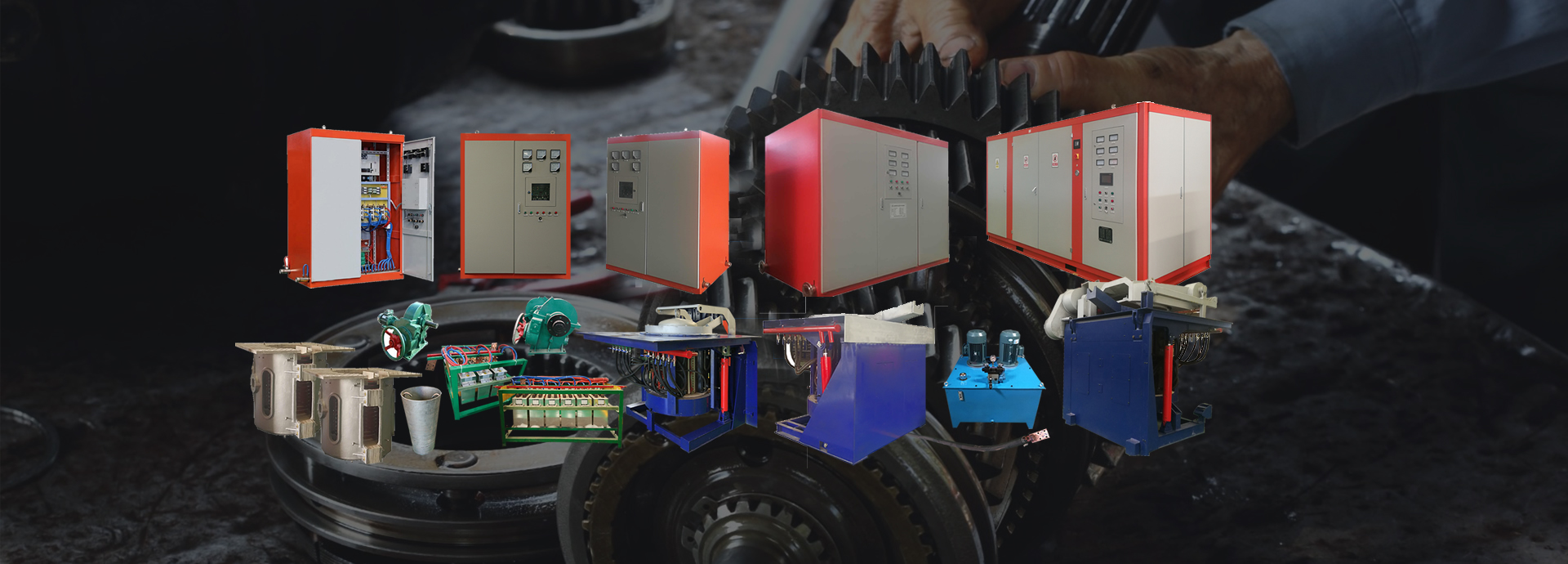

Foster Induction Private Limited is the Resilient Induction Brazing Machine Manufacturers in Gujarat. One of the defining features of our induction brazing machines is their efficiency and precision. Unlike flame-based brazing, induction heating uses energy wisely by only heating the targeted area to the precise temperature required for brazing. This results in lower energy consumption and faster cycle times, thus providing a highly cost-effective solution for industrial applications. The temperature controllable feature provides consistent repeatability in batch production and, therefore, is preferred in industries where precision is key.

We are the Advanced Induction Brazing Machine in Rajkot. Induction brazing machines prevent thermal distortion and damage to the parts by local heating. In cases of applications dealing with small or intricate parts, it will be of particular importance since the heat has to be applied very precisely to avoid warping or cracking. The base materials will retain their properties and structural integrity since the heat has been concentrated precisely on the joint. Induction brazing offers quite a few important advantages over other, more traditional flame-based or furnace-based brazing methods. These often do not include accurate temperature controls, leading to overheating or underheating and therefore compromised quality of the joints. They are also slower and more energy-intensive.

Choose us for all the needs of your Induction Brazing Machine Exporters and Suppliers in India. Our induction brazing machines realize faster speeds, greater accuracy, and better energy efficiency, which tends to reduce the operational cost considerably over a certain period of time. Our induction brazing machines are designed with strength and reliability in mind. Constructed from superior quality components, including durable induction coils and robust power systems, these machines can perform very well even under the most demanding conditions in industry. Advanced cooling systems prevent overheating and allow for continuous operation without interruptions, ensuring more productivity.

We’re here to assist you with all your induction system needs! Reach out to us today, and let’s discuss how we can help your business achieve excellence with our innovative solutions.